of Special Equipment

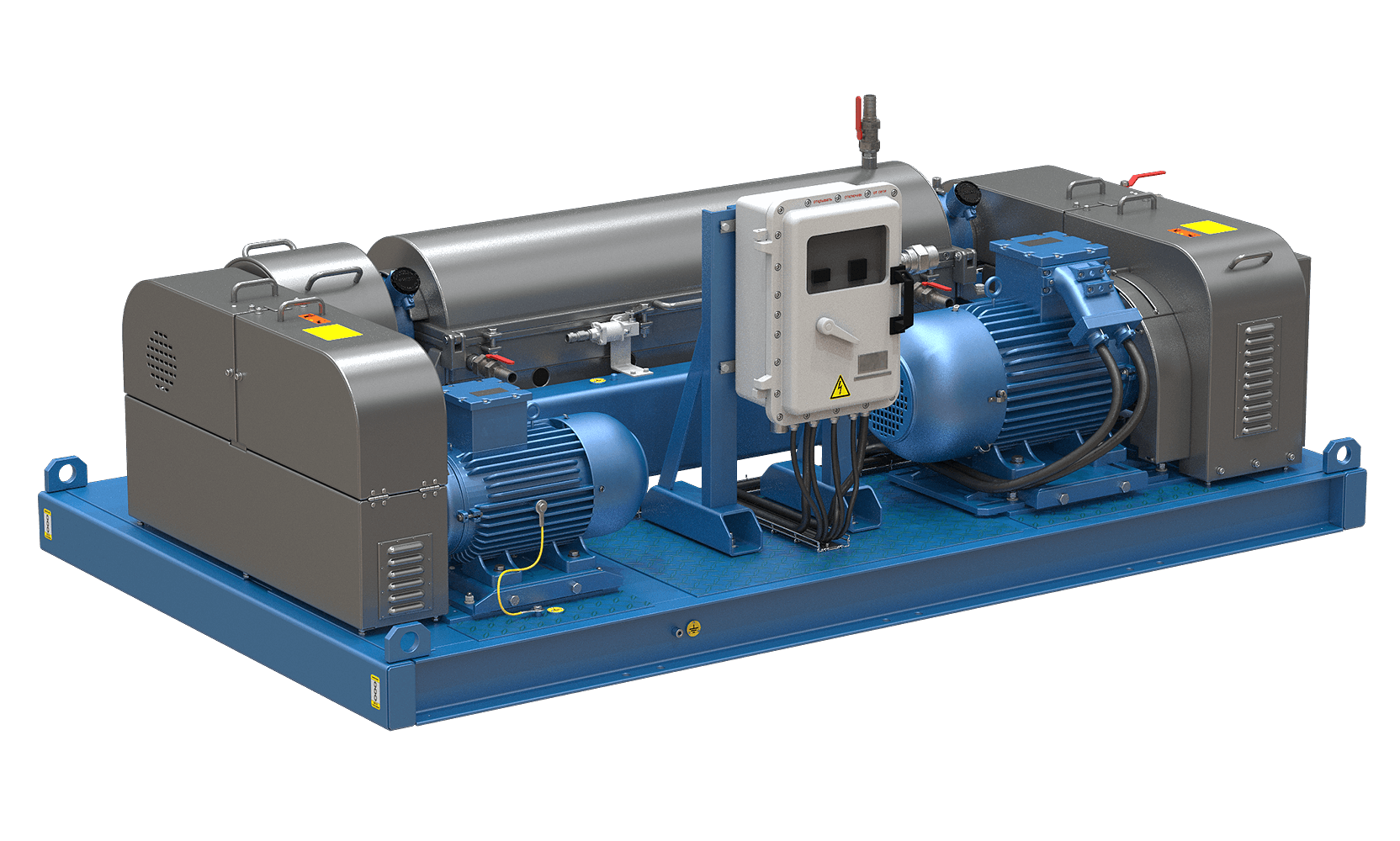

Decanter Centrifuge CRUISER MK 758-50-52-M

Design and performance

High-speed horizontal axis decanter with high capacity and high solution purity, equipped with a local control system. It has a modification to work in a marine climate.

Local control system

The centrifuge control system performs the following functions:

- Automatic optimization of performance characteristics depending on the load on the engines;

- Information data exchange with the system of control and management of drilling equipment;

- Control of the centrifuge condition and display of operating parameters on the monitor;

- Smooth regulation of the feeding screw pump;

- Smooth regulation of the screw speed;

- Smooth regulation of the centrifuge drum rotation speed;

- Automatic blocking of the feeding screw pump switching on until the centrifuge enters the operating mode;

- Temperature control of bearings and torque of the main and additional centrifuge motors;

- Temperature and vibration control of drum bearings;

- Blocking of start of electric motors with open casings;

- Blocking of the auxiliary electric motor of the drive from excess of speed;

- Constant monitoring of accidents and warnings.

Drive unit

Explosion-proof electric motors have power of 37 kW (main drive) and 15 kW (auxiliary drive) with frequency control. Precise balancing ensures low vibration and noise levels.

Durability

All main parts and fasteners of the working part of the centrifuge are made of stainless steel. The service life of the conveyor auger is increased due to the use of brazed plates made of wear-resistant tungsten carbide. High-strength, corrosion-resistant cast iron nozzles are used to increase the life of the sludge outlets. Details of the centrifuge body in the places of impact of the drilling mud flow have additional protection.

Safety

The design of the centrifuge has additional safety devices:

- Drum bearing vibration sensors;

- Temperature control sensors for drum bearings;

- Limit torque clutch with limit switch;

- Limit switches for casings and guards;

- Temperature sensors of bearings and windings of electric motors;

- Screw pump dry running protection sensor.

|

Parameter name |

Value | ||||

|---|---|---|---|---|---|

|

Processed material type |

Water or oil-based drilling mud |

||||

|

Processed material relative density |

Max. of 1450 kg/m3 |

||||

|

Processed material relative pH level |

4 - 12 | ||||

| Processed material temperature, max. | 95 °C | ||||

|

Conveyor type |

Auger, axial flow |

||||

|

Drum: length x width |

1479 x 356 mm |

||||

|

Working parts material |

Stainless steel | ||||

|

Size of removed particles, min. |

2-3 micron |

||||

| Centrifugal force at rotation drum speed 3250 rpm, max. | 2100 G | ||||

|

Maximum productivity |

50 m3/h |

||||

|

Overall sizes |

3000 × 1778 × 1100 mm |

||||

|

Mass |

3100 kg |

||||

|

Main drive power |

37 kW |

||||

|

Reverse drive power |

15 kW | ||||

|

Mains frequency |

50 Hz |

||||

|

Voltage |

3PЕ~50Hz 380 V |

||||

| Voltage of the local control system (LCS) |

2PЕ ~50Hz 220 V |

||||

|

Explosion protection |

IIGbcIIBT4 |