of Special Equipment

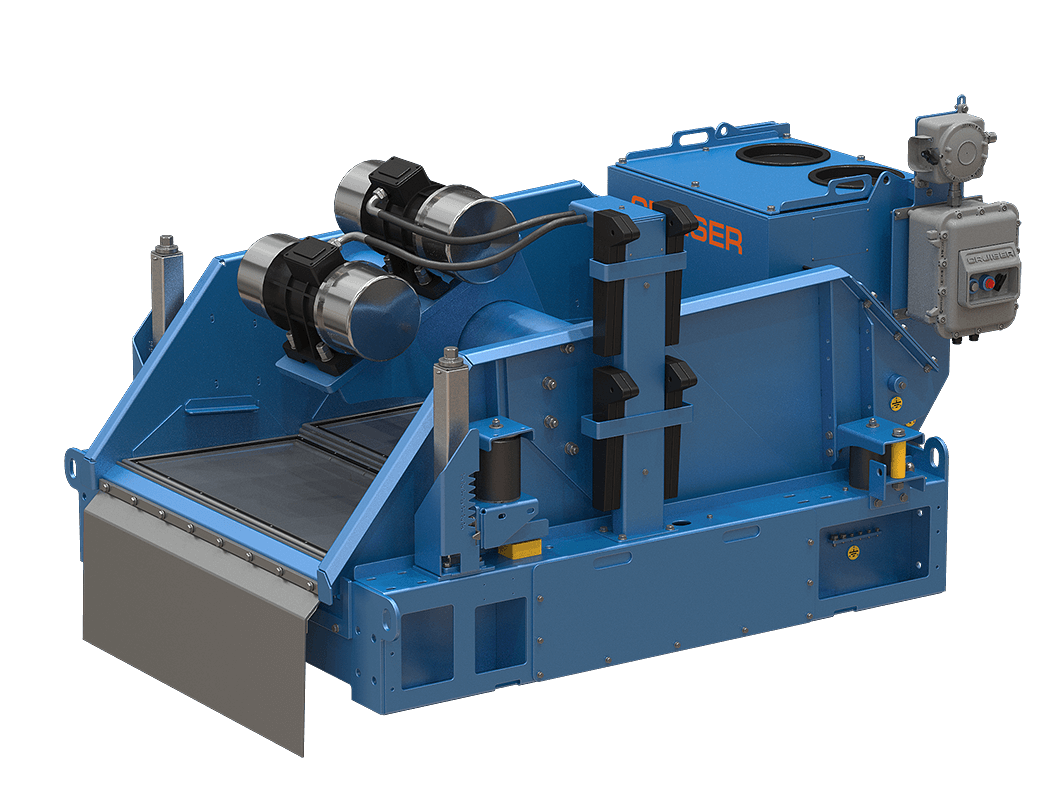

Shale Shaker CRUISER МК 700-1-03-1-UHL3.1-100

CRUISER shale shakers are designed for the primary removal of solids (sludge) from water-based or hydrocarbon-based drilling mud in mud cleaning systems for drilling oil and gas wells.

Operating modes and performance

Two types of oscillations are implemented on shale shakers: linear and elliptical. Depending on this, uniform transportation of sludge or maximum productivity is carried out.

Design

Short shale shaker. All-welded vibration frame. Reliable and easily removable wedge fastening of screen panels. Reinforced jacks for adjusting the angle of inclination.

Reliability and operating conditions

High reliability vibration motors with low noise levels. Shale shakers of own production of increased service life. Durable polyurethane screen panel seals. Vibrating frame springs are made of high-strength steel.

Corrosion protection

The working part of the vibrating frame is made of stainless steel. The design has a 3-layer coating of premium class enamel with increased durability.

Safety

All electrical equipment is explosion-proof.

| Designation | Value |

|---|---|

|

G overload factor — Linear — Ellyptical |

7 – 7,5 6 – 6,5 |

|

Deck number, pcs |

1 |

|

Screen amount, pcs |

3 |

| Total screen area, m2 | 2.01 |

| Screen non-blanked area, m2 | 1.82 |

|

Screen panel sizes: length х width х height, mm |

1165 х 584 х 40 |

|

Maximum throughput when drilling on water, l/s |

Up to 31 |

|

Angle inclination adjustment possibility, degrees |

+3, -3 |

|

Overflow height, max, mm |

750 |

|

Receiver type |

Overflow |

|

Vibration motor number |

2 |

|

One vibrator power, kW |

1.65 |

|

Rotation frequency, rpm |

1500 |

|

Voltage, V |

380 |

|

Current frequency, Hz |

50 |

| Overall sizes, max: length х width х height, mm | 2352 × 1748 × 1314 |

|

Mass, max, kg |

1423 |